3D printing, also known as additive manufacturing (AM), is redefining the landscape of biomechanical engineering, especially in creating highly customized prosthetics and implants. This technology’s ability to construct precise, patient-specific models has led to significant advancements in medical engineering, opening new possibilities for improving patient outcomes through custom-made solutions.

Advancements in Prosthetic Customization and Functionality

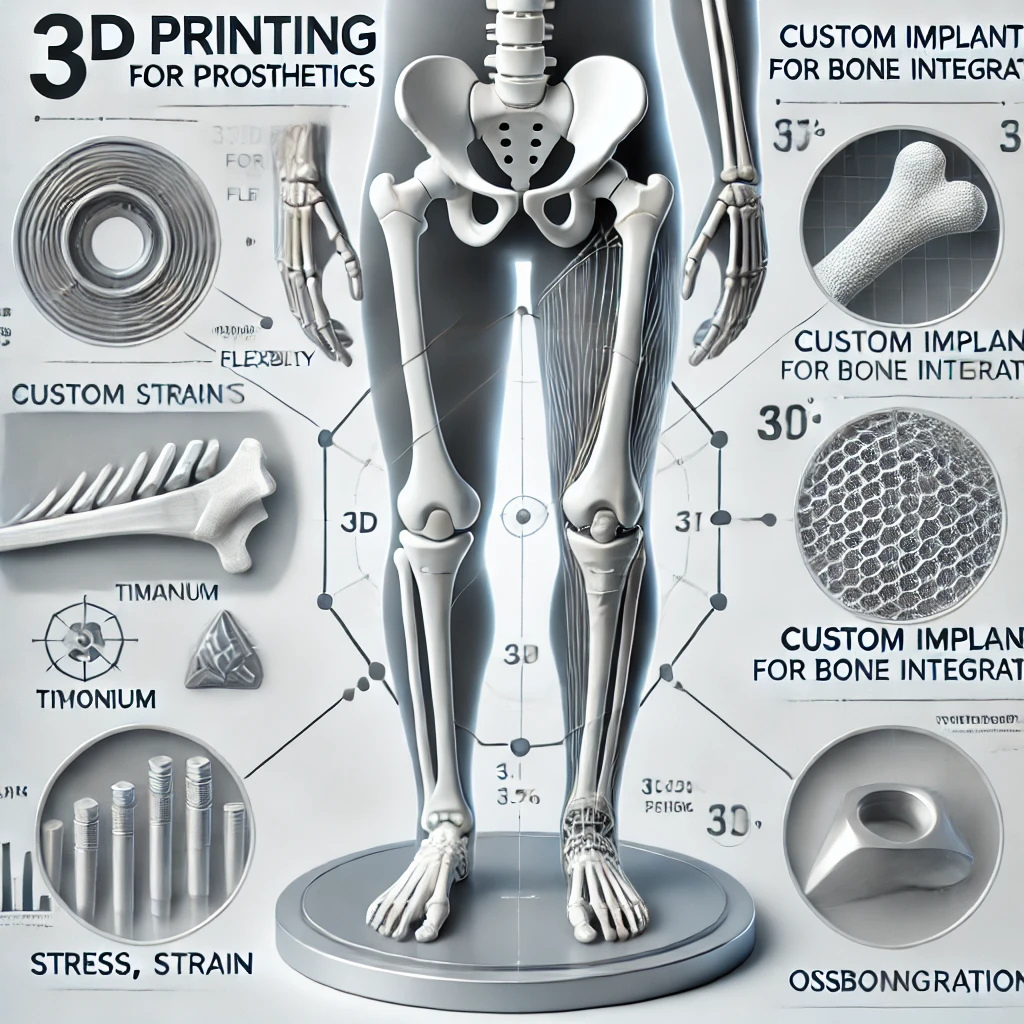

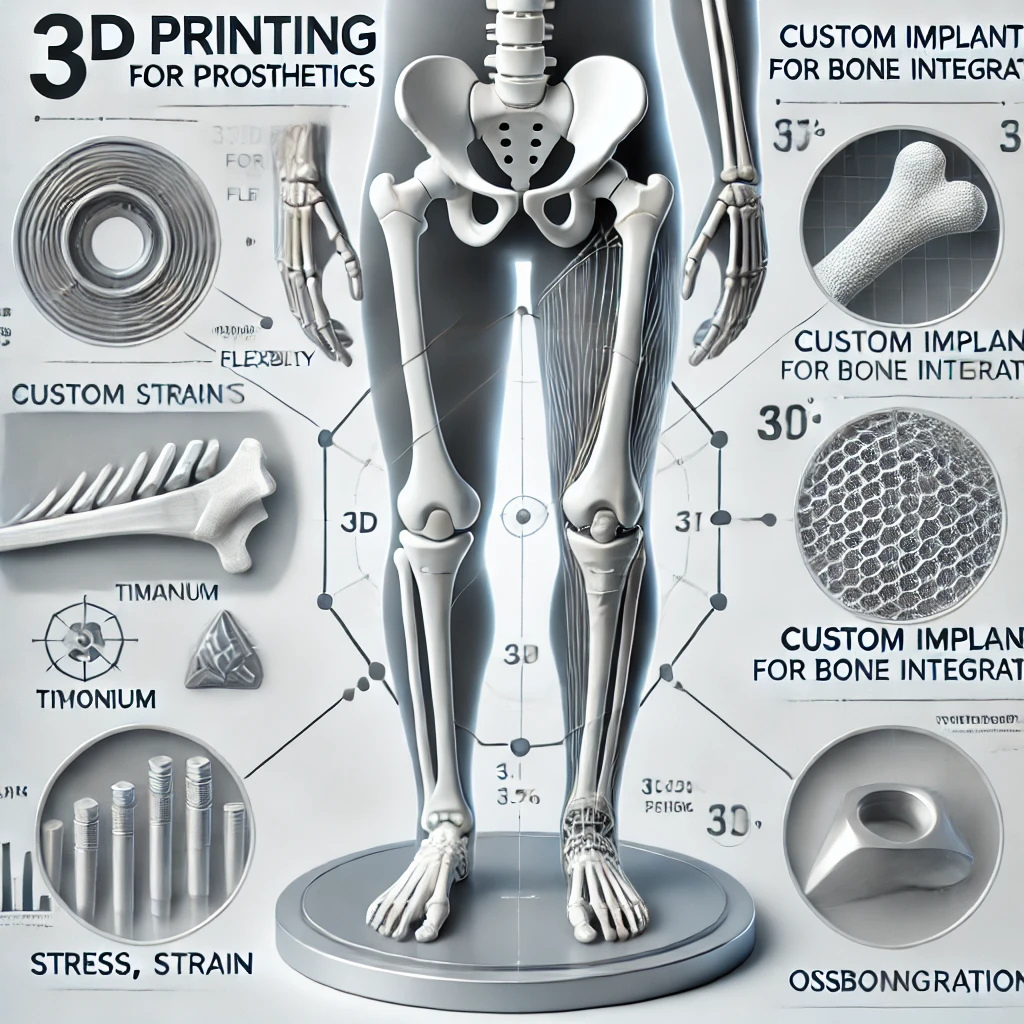

In traditional prosthetic design, the focus was primarily on static fit and structural durability. However, with the advent of 3D printing, engineers can now design prosthetics that precisely mirror individual limb geometry, thus enhancing functional efficiency and comfort. The 3D printing process allows engineers to develop prosthetics by scanning the patient’s residual limb and creating an exact digital model, subsequently translated into a physical object. An essential engineering consideration in prosthetics design is weight-bearing capacity, which is assessed by understanding the forces acting on the prosthetic limb. The structural integrity of prosthetics can be represented by stress (σ) and strain (ε) formulas:

F = σ * A

Where “F” stands to be applied force whereas “A” represents cross-sectional space. This helps determine whether materials such as thermoplastic or carbon-fiber-reinforced nylon are ideal for the prosthetic limb, as they provide high tensile strength and durability while keeping the weight minimal. For instance, materials engineered for strength-to-weight optimization allow active lifestyle prosthetics to absorb greater forces during dynamic activities. 3D printing’s customization also extends to biomechanics, where flexible joints within prosthetics can emulate natural movement by incorporating hinges or compliant materials that mimic joint flexibility, improving balance and range of motion (Park et al., 2023).

3D Printing and Custom Implants: A Paradigm Shift

In implant design, 3D printing facilitates the production of tailored structures that fit precisely into the patient’s skeletal system, reducing the need for intraoperative adjustments. Traditional implants often involve generic shapes and sizes, making it challenging to achieve a perfect fit. 3D printing’s precision minimizes the gap between implant and bone, reducing healing time and improving mechanical stability. In engineering terms, the concept of osseointegration (the process by which bone attaches directly to the implant surface) is critical to implant success. Engineers create implants with porous structures using titanium to encourage bone growth. The degree of porosity impacts the overall mechanical performance, which can be estimated using Young’s modulus “E” and Poisson's ratio “ν”:

E = σ / ε

Where “p” is the porosity factor. This model enables engineers to adjust the implant’s mechanical behavior for osseointegration without compromising strength (García-Muiña et al., 2019). A recent application of 3D-printed porous titanium implants demonstrated success in mandible reconstruction, using a precise fit with the patient’s jaw contour to ensure structural and functional integration (Darwich et al., 2020).

Innovations in Materials and Multi-Material 3D Printing

One of the most critical aspects of biomechanical engineering is material selection, especially for implants and prosthetics that require high performance under biomechanical loads. Traditional metal alloys like cobalt-chrome have been replaced in many cases with materials such as Polyetheretherketone (PEEK) due to its high-performance profile, which includes biocompatibility, imaging compatibility, and fatigue resistance (Ma et al., 2021). Multi-material 3D printing, which enables the combination of rigid and flexible materials in a single product, allows for the precise integration of elasticity into specific regions of prosthetics or implants, such as hinge joints, while maintaining rigidity where needed. This type of structural flexibility can be represented in calculations of stress distribution, particularly by using von Mises stress for complex geometries, a critical factor in biomechanical applications:

σ = √(σx² + σy² - σx * σy + τxy²)

Here, σx and σy represent principal stresses alongside τxy to be shear stress. This stress assessment helps in designing devices with uniform distribution to avoid localized failures, which is especially relevant in load-bearing implants (Han & Bai, 2020).

Future Innovations: AI and 4D Printing

Advances in artificial intelligence (AI) have enabled new possibilities in 3D printing. AI algorithms can optimize implant designs based on biomechanical data, adjusting the material distribution and thickness to match specific load-bearing requirements. AI also supports predictive analytics in demand forecasting and inventory management for custom implants, enhancing resource efficiency and minimizing waste in the production chain (Amosu et al., 2024). In addition, 4D printing is an emerging technology within biomechanical engineering. By using shape-memory polymers (SMPs), implants or prosthetics produced via 4D printing can adapt over time to the changing anatomy of patients, particularly valuable for young patients whose bodies are still developing. SMPs can alter their shape in response to environmental triggers such as temperature or hydration, providing a level of adaptability previously unseen in traditional materials (Ramezani & Ripin, 2023).

Thus, 3D printing has established itself as a cornerstone of biomechanical engineering, fundamentally transforming the capabilities and scope of patient-specific prosthetics and implants. By integrating concepts such as load distribution, osseointegration, and multi-material design, engineers are leveraging 3D printing to optimize device performance and durability. As these technologies evolve and intersect with AI and 4D printing, the role of biomechanical engineers will continue to expand, pushing the boundaries of customized medical care and biomechanics. Through technological innovation and precise engineering calculations, 3D printing in biomechanical engineering not only meets but exceeds the growing demands of modern healthcare, heralding an era where personalized medicine and patient-centric solutions become the new standard.

References

- Amosu, O. R., Kumar, P., Ogunsuji, Y. M., Oni, S., & Faworaja, O. (2024). AI-driven demand forecasting: Enhancing inventory management and customer satisfaction. World Journal of Advanced Research and Reviews, 23(2), 708–719. https://doi.org/10.30574/wjarr.2024.23.2.2394 [Artificial Intelligence, Algorithms, Predictive Analytics, Demand Forecasting, Inventory Management]

- Darwich, K., Ismail, M. B., Al-Mozaiek, M. Y. A.-S., & Alhelwani, A. (2020). Reconstruction of mandible using a computer-designed 3D-printed patient-specific titanium implant: a case report. Oral and Maxillofacial Surgery, 25(1), 103–111. https://doi.org/10.1007/s10006-020-00889-w [3D Printing, Osseointegration]

- Han, D., & Bai, T. (2020). Design optimization of a simple step-stress accelerated life test – Contrast between continuous and interval inspections with non-uniform step durations. Reliability Engineering & System Safety, 199, 106875. https://doi.org/10.1016/j.ress.2020.106875 [Flexibility, Stress Assessment]

- Ma, H., Suonan, A., Zhou, J., Yuan, Q., Liu, L., Zhao, X., Lou, X., Yang, C., Li, D., & Zhang, Y. (2021). PEEK (Polyether-ether-ketone) and its composite materials in orthopedic implantation. Arabian Journal of Chemistry, 14(3), 102977. https://doi.org/10.1016/j.arabjc.2020.102977 [Polyetheretherketone, Imaging Compatibility]

- Park, J. W., Greenspan, B., Tabb, T., Gallo, E., & Danielescu, A. (2023). 3D Printed Energy Return Elements for Upper Limb Sports Prosthetics. Prosthesis, 5(1), 13–34. https://doi.org/10.3390/prosthesis5010002 [Prosthetics, Flexible Joints]

- Ramezani, M., & Ripin, Z. M. (2023). 4D Printing in Biomedical Engineering: Advancements, Challenges, and Future Directions. Journal of Functional Biomaterials, 14(7), 347. https://doi.org/10.3390/jfb14070347 [Shape-Memory Polymers, 4D Printing]